Prusa MK3S Running Marlin 2.0.3 on SKR v1.4 Turbo?!

Intro

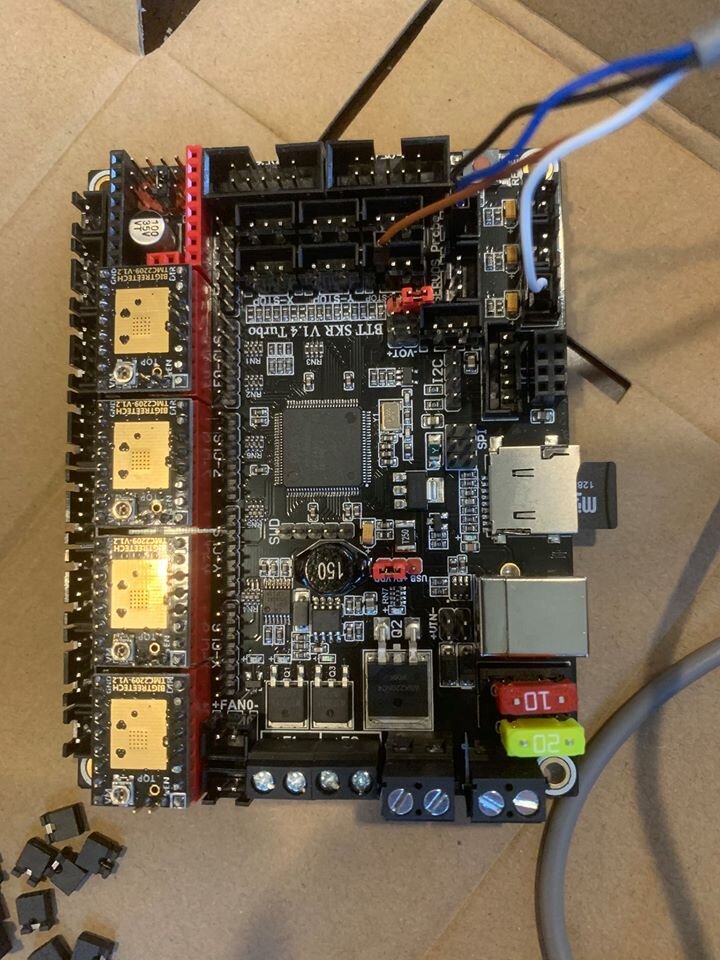

Over the week I took some time to do something completely random and unplanned. I decided to disassemble my perfectly working MK3S Bear and remove the Einsy Rambo board. I replaced that with the newish BTT SKR v1.4 Turbo 32 bit board running TMC2209 stepper drivers (The standard SKR v1.4 isn’t much different, this one just has a small boost in the processor speed). This was the first time I’ve done a board swap on my printer and the first time in a long time since I’ve messed with vanilla Marlin. Side note, I’m not a Marlin expert or know a lot when it comes to configs so excuse my noob-ness if I got something wrong.

I watched a few videos that were recently put out by Chris Warkocki on how to configure Marlin for the SKR v1.4 board to run on the MK3S. I did some searching of my own as well and compiled my firmware, that was probably the easiest part of this conversion. I then proceeded to study the wiring diagram provided on his Github and figured out where everything was going before attempting to change all of my connectors. I’m sure someone out there will make a breakout board or conversion cables but I figured that re-crimping the wires to 2.54 JST XH wasn’t that difficult and if I ever want to switch back to the Einsy Rambo, I could just change the connectors on the Einsy Rambo board itself (I’ve done this for a few things already like the bed and hotend thermistors). The fans themselves also needed to be swapped out for 24v fans, luckily I had a 5015 blower and 4010 fan on hand. I was also informed that you could use the end stops to plug the 5v fans in, but I’d stick with the 24v fans.

Setting the board up

The board itself needed a few things done before it would work the way I needed it to. The first thing was removing the jumpers on the SKR v1.4 board for where the TMC2209 stepper drivers were going. Only the 3rd jumpers should remain on all of the steppers on the board. Refer to Chris’ Wire Guide PDF that I linked above if you don’t know what I’m talking about. The other thing that needed to be done was one of the pins on the TMC2209 that controlled the extruder needed to be snipped off. According to Chris, the filament runout sensor won’t work if that pin isn’t clipped. The Extruder stepper is the on with E0-CLS labeled under it, I didn’t realize this the first time I was connecting everything.

Re-crimping the wires did take some time, but isn’t too difficult if you’ve crimped wires before. I believe most of the wires are about 26AWG so they’re not too thin or difficult to work with. The 2.54 JST XH connectors I used were from a set I bought a year ago . If you’ve never crimped cables before there are a ton of YouTube videos out there that show you exactly how to do so. You can also opt to just buy pre-crimped cables and solder them if you find that easier to do. You’ll also need to recrimp your power cables and heated bed. These cables use ferrule pins instead of the fork spade wire connectors that are used on the Einsy. Something to note is that on Chris’ diagram he has the Hotend cooling fan show connecting to the FAN1 connector, the fan should actually be connected to the HE1 connector, so you’ll need to crimp those wires with ferrule pins as well.

After getting all my cables in order I tried to run them through the newly printed SKR v1.4 case and came across my first issue: My cables from my power supply were way too short. I took the opportunity to remove a set of cables from the power supply that were no longer needed. Since the SKR v1.4 only needs a single pair of Power In cables compared to the Einsy Rambo which required two sets of Power In and Power Out cables. Something that I had to be mindful of was the fact that one Z axis motor goes into the ZMA port and the other motor goes into the E1M port, that way the steppers will both be independently driven by two stepper drivers (The stepper driver with Z-CLS under it and the one with E1-CLS under it) as opposed to being controlled by just one (Just the Z-CLS), utilizing all 5 stepper drivers. At the moment my cables are way too long and need to be cleaned up, but it’s more a proof of concept than anything else. I just want to get the new system up and running and cable management will come later. Hopefully my picture below gives you a good idea of where cables are suppose to go.

All wires connected

The second issue I came across was the lack of response from my 2004 LCD. I powered everything on and attempted to connect it via Pronterface and was able to connect and send commands to it. The same was true for when I tried to use OctoPrint, so I knew everything was working and I just issues with the LCD. After consulting with Chris I realized that my issue was I needed to clip the key on the ribbon cables and flip them. After doing this I was able to get the LCD to light up and work. I failed to realize that the wiring diagram also mentioned this, so it was my mistake.

With all the cables connected I ran a few tests, I tried to home my printer and didn’t realize that my PINDA probe had been moved way too high, I ended up crashing the nozzle into the bed and probably bent my heated bed. After fixing the PINDA I was able to home properly, the difference is that with the current settings on Marlin the bed homes to the corner when you home X and Y, but if you home all the axises it’ll go to the middle of the bed. So be sure to make the proper changes to your Start Gcode on your print profiles or they won’t work well.

Notes and after thoughts

Also, note that the Prusa specific commands no longer work, so G80 and G81 no longer function like they did on the Einsy Rambo. Instead if you of using G80, you’ll now use G29 to run mesh bed leveling and G420 V to view the results. I’m sure there are others but those are the two that I noticed right off the bat. So changing the mesh leveling commands on your startup scripts is a must. G28 also now homes to the middle as oppose to the left corner like it did on the Prusa firmware, so G28 Y X needs to be used instead.

I haven’t had too much of a chance to play with it and I’m still working out a few things so I’ll do an update on that later, but just wanted to write a post about my initial impressions of getting the board setup and working. The first few things I did was test the homing, test the fans, test the PINDA, filament runout sensor, new features of Marlin, and do PID calibrations on the hotend and bed. I plan on doing a few test prints once I get things dialed in a bit more and will post a more thorough overview of my thoughts at that time.

Forewarning

Please understand that this is no longer the Prusa firmware so you can severely damage your bed, nozzle, printer, and possibly yourself if you aren’t careful. No one will be responsible for your mistakes. If you do decide to do the conversion, stand by the printer while you do all your tests in case you need to shut it off immediately. Vanilla Marlin doesn’t hold you hand as much as Prusa Marlin, so be aware that it is easier to break things with this firmware. I've actually gouged my textured PEI sheet a few times and slammed my nozzle into the bed more than once. For example, I finished a print and decided to home my printer while I was out and forgot that now when the printer homes it goes to the middle and tries to home the nozzle as well. My nozzle constantly slammed into my print bed as I watched helplessly until it finally halted. That's one of the many things that can happen if you're not paying attention.

Here’s a summarized list of complications and things I came across after making the conversion

Cables from the power supply need to be extended

2004 LCD cables need to be flipped (notches need to be clipped)

Both fans need to be replaced with 24V versions ( 5015 blower, 4010 axial)

All connectors need to be replaced with either 2.54 JST XH or wire ferrules

Hotend fan needs to be be plugged into H1 with wire ferrules

Power In cables from power supply need to be removed

G80 and G81 no longer function

If you want to auto home to the corner G28 Y X needs to be used, Homing Z makes the nozzle move to the middle as per Safe Homing feature in Marlin (UPDATE: This has been changed by Chris’ new firmwares)

Things I purchased/used for this conversion (Links are Amazon affiliated)

The SKR V1.4 Turbo board itself and TMC2209 stepper drivers, I ordered from Amazon because at the moment nothing is getting out of China due to the Corona Virus, I’m sure it’s a lot cheaper but this was delivered next day: BigTreeTech SKR V1.4 Turbo with TMC2209

Since I needed longer cables, I decided to purchase 14 gauge silicone wires from BNTECHGO one of my favorite brand for wires. Silicone works are much easier to work with since it has more flex and they’re also heat resistant: BNTECHGO 14 Gauge Silicone Wire 10ft Red and 10ft Black

The fans needed their wires extended so I used silicone wires from my 26 gauge spool: BNTECHGO 26 Gauge Silicone Wire spool red and black

If you don’t already have a 24V 5015 blower fan, just get a set of two from Amazon. I’m still looking into what fans are actually the best but this is what I’m temporarily using: 2x 5015 DC Brushless Blower Fan 2 Pin

Since the SKR v1.4 board requires 24v fans, I replaced my hotend fan with one of these that I had on hand: 1x 4010 DC Axial Fan 2 Pin

You don’t have to crimp your power cables, but I found it neater than just having bare wire connected to the terminals, I used wire ferrules similiar to these: Wire Ferrules Kit and Crimper

Since almost all your connectors(stepper motors, fans, PINDA, filament runout sensor, and thermistors) need to be replaced, I recommend getting a kit if you don’t already have one: 2.54mm JST-XH connector kit and Crimper

Things left to do:

Refine Start Gcode

Work on bed leveling

Figure out slicer settings

Cable management

Explorer Marlin configs even more

Compare prints from Einsy vs SKR

Research better fans

Upgrade screen to TFT

Add LEDs?